The effect of using colmatants lasts for the entire time required. To decolmatize the well at the end of work, a hydrochloric acid solution is used, which completely neutralizes the effect of the colmatant.

Application of organic colmatant is very wide: it is used in the oil and gas industry; in technological processes of construction and repair of wells in order to eliminate absorption of drilling mud, as a sorbent for oil products, in various industries as an abrasive material.

Colmatants are widely used in the oil and gas industry. Thanks to their use the drilling process is faster and more efficient. These additives plug holes, cracks, etc. in the rock being drilled, so that the mud is not absorbed into the formation. They also regulate the internal pressure in the well. Colmatant helps to perform the best and most effective penetration of productive rock formations.

KEY BENEFITS OF DRILLMIX BRIDGING AGENTS

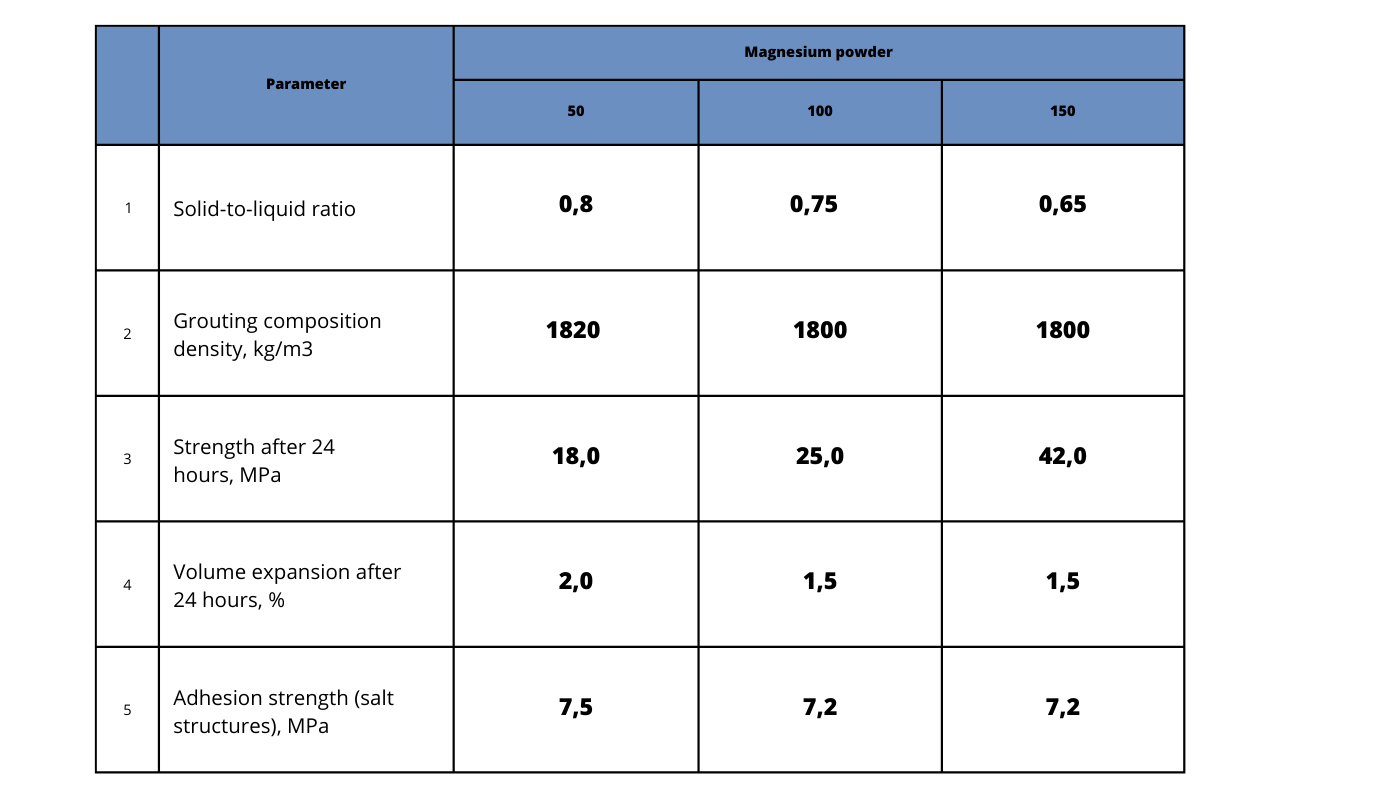

Properties of a cement stone formed from a magnesium-based grouting composition produced

Cement stone, formed on the basis of magnesia plugging mixtures, not only allows to isolate well and reliably the inter-casing space, but also provides bonding strength with the salt formation rock greater than the strength of the rock itself.

Materials and reagents containing various forms of magnesium oxide (MgO) are widely used at all stages of construction and operation of oil and gas wells. In most cases, technologies and materials based on magnesium oxide are designed to solve problems that conventional technological solutions fail to cope with.

MAGNESIUM OXIDE FOR THE DRILLING, CEMENTING, SERVICING, AND ABANDONMENT OF OIL AND GAS WELLS ON LAND AND OFFSHORE

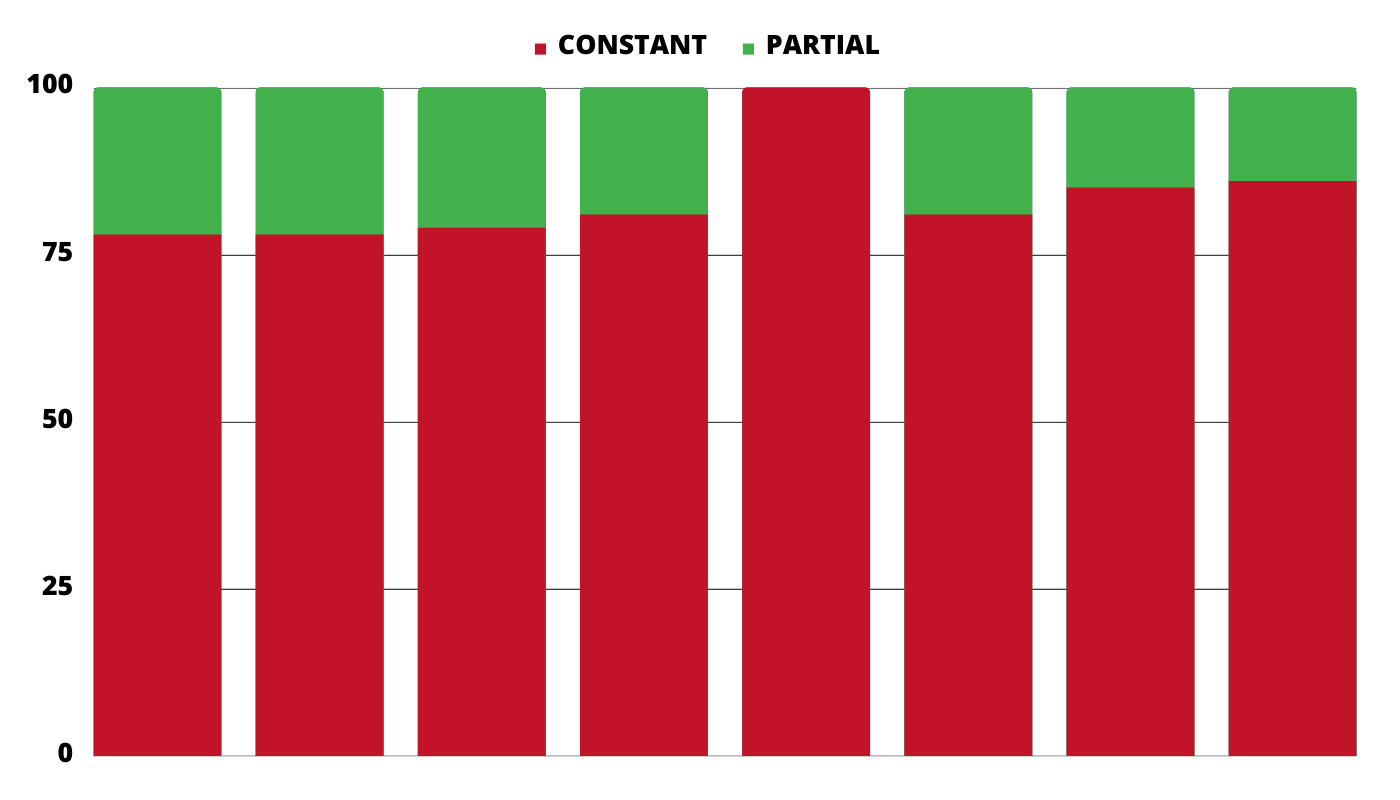

Acoustic cement bond log of casing strings cemented with magnesium-based grouting compositions produced

The unique properties of MgO-containing materials allow not only to achieve the required efficiency, but also to fulfill the tasks with minimal material and time costs. Today these materials are successfully used for:

- cementing of casing strings in saline sediments;

- implementation of repair-isolation works;

- cementing of inter-casing space in gas wells in order to prevent inter-casing pressure.

Our products are used in many industries, from industrial and civil engineering to drilling and operating oil and gas wells.

It is used both as a raw material and a finished product in the following areas:

- Construction: building materials and mixtures;

- Oil and gas industry: grout compositions;

- Energy and chemicals industry: water purification and softening;

- Fertilizer industry: anti-caking agents for mineral fertilizers.

Magnesium powder is produced by directed heating of magnesite at a temperature of 850-1000°C with subsequent grinding in a specialized mill. The product has a predetermined chemical activity thanks to the technologies that allow adjustment of the time and temperature of heating and regulation of the fractional composition of grinding.

Magnesium powder is used in the rubber, electrical, construction, chemical, and other industries.

Magnesite is highly hygroscopic and resistant to low and high temperatures. Coating surfaces with compounds containing magnesium chips increases their sound insulation and does not exert a significant weight load. It also provides electrical insulation properties and is used in the construction and repair of thermal units and electrolyzers.

Magnesite is highly hygroscopic and resistant to low and high temperatures. Coating surfaces with compounds containing magnesium chips increases their sound insulation and does not exert a significant weight load. It also provides electrical insulation properties and is used in the construction and repair of thermal units and electrolyzers.

ORGANIC BRIDGING AGENTS

9

DrillMix bridging agents are partially acid-soluble (from 25 to 45%, depending on the formulation), which ensures their safe use in the areas of the production zone.

8

DrillMix bridging agents are compatible with all types of drilling and flushing fluids; they do not react with the components of drilling fluid and do not degrade its performance.

7

In mining and geological conditions where traditional medium and coarse bridging agents are used, our universal fine-grain DrillMix material can be used, which simplifies storage and excludes the use of multiple products for various complications.

6

With DrillMix products, the minimum possible permeability of the filter cake is ensured not by its thickness but by the packing density of bridging agents, which is guaranteed to reduce the risk of sticking, improve keyseat reaming, and reduce hydrodynamic resistance during drilling fluid circulation.

5

Its optimal composition eliminates the human factor when selecting the formulation of a bridging agent and reduces the time spent on its preparation, as well as the total content of the agent in the solution. As soon as any bridging agent is an abrasive, this is critical for equipment wear.

4

DrillMix lost-circulation materials do not require various biopolymers and structure formers to improve the properties of the drilling fluid. DrillMix is easy to use, saves expensive reagents and working time, and eliminates human errors.

3

All types of DrillMix lost-circulation materials can be used in drilling with natural water-based drilling fluid without any other reagents and show excellent results. The bridging ability of a suspension containing technical water and DrillMix (100 kg/m3) is 77-81%.

2

Optimally selected fractional and chemical compositions allow for improved bridging ability with significantly lower consumption. For example, the bridging ability of a biopolymer-inhibited drilling fluid with a traditional bridging agent (150 kg/m3) is 41-43%. The bridging ability of the same solution with DrillMix lost-circulation materials (80 kg/m3) is 88-90%.

1

Unlike traditional lost-circulation materials (nutshell, rubber crumb, seashell, etc.), DrillMix lost-circulation materials are multicomponent and include a variety of modifying chemical reagents (biopolymers, structurants, binders, weighting agents, fluid loss reducers, etc.).

MAGNESIUM POWDER

FOR THE OIL AND GAS INDUSTRY

DrillMix bridging agents

MAGNESIUM OXIDE